Choosing the right cover glass for LCD displays is a crucial aspect that can significantly impact both the functionality and aesthetics of your device. The right cover glass for LCD display must balance various factors, including durability, optical clarity, and environmental resistance to ensure optimal performance. As advancements in display technology continue to evolve, the options available on the market have expanded dramatically, making the selection process more complex.

In this guide, we will explore the different types of cover glass materials, their respective benefits, and considerations that should guide your decision. Whether you are designing a consumer electronics device, an industrial panel, or any other application involving an LCD display, understanding the properties that make up the perfect cover glass for LCD display is essential to enhance user experience and prolong the lifespan of your product.

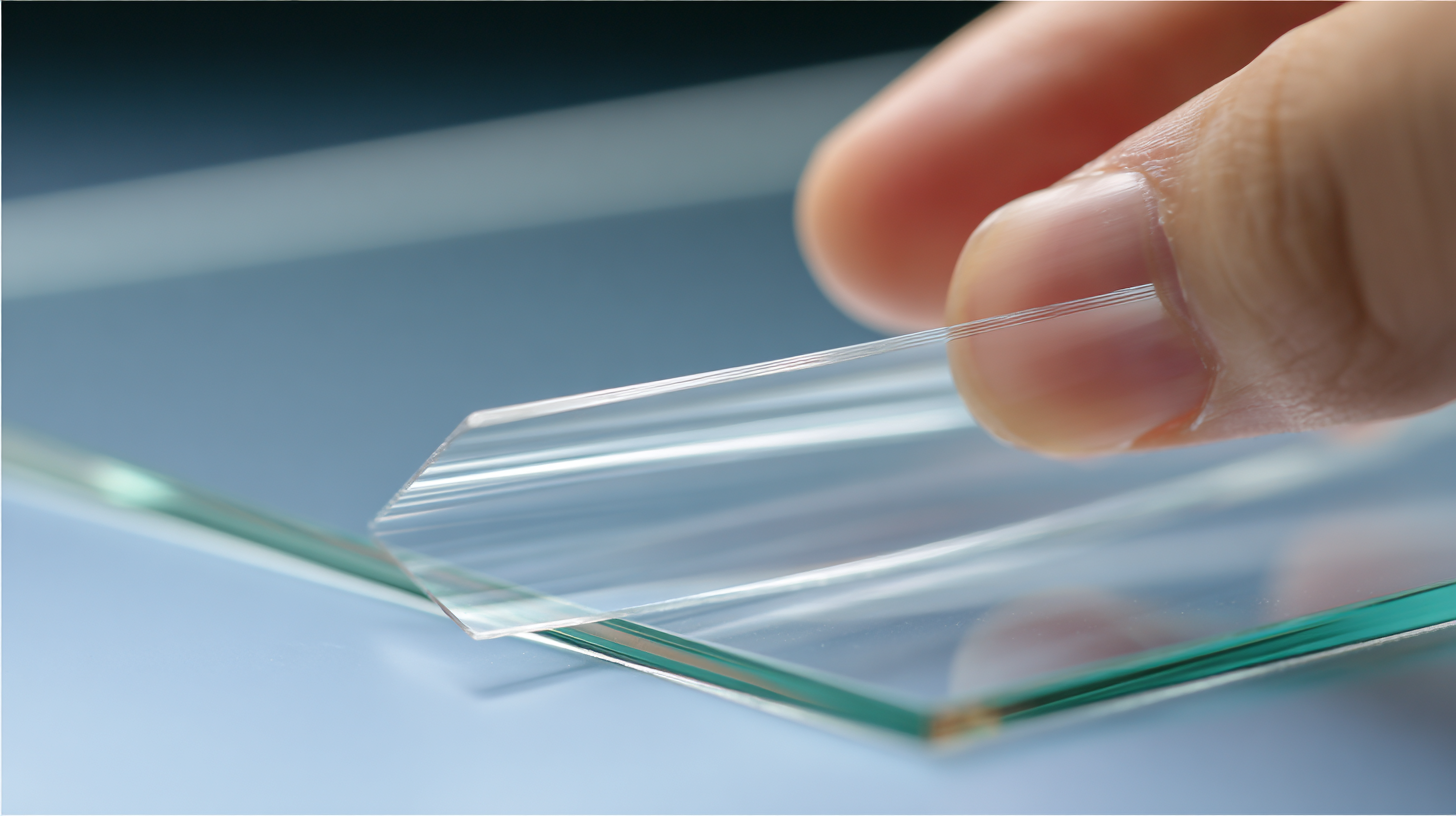

When selecting the appropriate cover glass for LCD displays, understanding the various types of cover glass available is crucial. Cover glass can vastly differ in terms of material, thickness, and surface treatment. The most common types are soda-lime glass, borosilicate glass, and chemically strengthened glass. According to industry reports, chemically strengthened glass is preferred in applications requiring durability and resistance to scratches, as it can experience up to 100 times the tensile strength of canister glass. This makes it ideal for smartphones and tablets where user touch is frequent.

In addition to material differences, coatings play a vital role in enhancing performance. Anti-reflective (AR) coatings can reduce glare by up to 90%, improving visibility in bright environments, which is essential for outdoor displays. Furthermore, protective coatings that offer oleophobic properties are gaining traction, making it easier to clean screens by repelling oils and fingerprints. With the global market forecasted to grow at a CAGR of 5.1% between 2023 and 2028, manufacturers should carefully consider which type of cover glass will best meet the specific requirements of their displays to optimize both functionality and user experience.

When selecting cover glass for LCD displays, assessing optical properties is crucial, particularly light transmission and reflection factors. According to a report by the Optical Society of America, high-quality cover glass can achieve up to 92% light transmission, significantly enhancing display brightness and visibility. This is essential for applications in bright environments or for devices requiring high image clarity.

In addition to light transmission, reflection is a key factor that impacts user experience and energy efficiency. A study published in the Journal of Display Technology highlights that anti-reflective coatings can reduce glare by as much as 50%, improving readability in direct sunlight and reducing eye strain. By choosing the right cover glass with optimized optical properties, manufacturers can elevate the performance of their LCD displays, making them suitable for a wider range of applications, from consumer electronics to industrial equipment.

| Glass Type | Light Transmission (%) | Reflection (%) | Coating Type | Hardness Rating |

|---|---|---|---|---|

| Standard Float Glass | 90 | 8 | None | 6H |

| Tempered Glass | 90 | 6 | Anti-Reflective | 9H |

| Low-Iron Glass | 93 | 5 | None | 7H |

| Frosted Glass | 75 | 10 | None | 6H |

| Protective Polycarbonate | 88 | 12 | Anti-Scratch | 5H |

When selecting cover glass for an LCD display, evaluating durability is paramount, with impact resistance and scratch resistance being two critical factors.

Impact resistance measures how well the glass can withstand external forces, such as drops or collisions. For applications where the display will be exposed to potential hazards, using tempered glass can provide enhanced protection. This type of glass is heat-treated to increase its strength, making it less likely to shatter upon impact.

Scratch resistance is equally important, particularly for displays that will be subject to frequent touch or interaction. Various coatings, such as Gorilla Glass or sapphire crystal, offer superior scratch resistance and can prolong the lifespan of the display. These materials not only preserve the visual clarity of the screen but also maintain its aesthetic appeal over time. When choosing a cover glass, it is essential to find a balance between these durability factors to ensure the display remains functional and visually appealing, regardless of the environment in which it is used.

When selecting the right cover glass for your LCD display, it's essential to take environmental factors into account, particularly temperature and moisture resistance. With many regions facing unprecedented heat waves, such as those recently reported in China with temperatures soaring above 44.4°C, the importance of heat-resistant materials becomes paramount. According to industry reports, the demand for heat-resistant cover glass has increased significantly as manufacturers strive to enhance the durability of their products against extreme temperatures.

Moisture resistance is equally critical, as elevated temperatures can lead to increased humidity levels, which compromise the integrity of LCD displays. The solar panel backsheet materials, which protect against moisture and UV radiation, serve as a valuable reference point for LCD cover glass selection. These materials are designed to withstand harsh weather conditions and prevent moisture ingress. Reports indicate that the global market for moisture-resistant materials is projected to grow substantially by 2032, highlighting the pressing need for robust solutions in display technology as environmental factors continue to evolve. By prioritizing temperature and moisture resistance, companies can ensure that their LCD displays maintain optimal performance in challenging climates.

When selecting cover glass for LCD displays, balancing costs with performance is crucial. High-quality cover glass can significantly enhance display durability, clarity, and functionality. However, opting for the cheapest option often leads to compromised quality, which might result in increased replacement frequency and potential damage to the underlying components. Understanding the specific needs of the display environment—such as exposure to impact, temperature variations, and moisture—is essential in making a more informed decision.

When selecting cover glass for LCD displays, balancing costs with performance is crucial. High-quality cover glass can significantly enhance display durability, clarity, and functionality. However, opting for the cheapest option often leads to compromised quality, which might result in increased replacement frequency and potential damage to the underlying components. Understanding the specific needs of the display environment—such as exposure to impact, temperature variations, and moisture—is essential in making a more informed decision.

Investing in superior cover glass can yield long-term benefits. While the initial expense may be higher, the performance advantages—like improved scratch resistance and optical clarity—can lead to reduced total cost of ownership. In fast-paced industries where displays are exposed to harsh conditions, the right cover glass can therefore preserve not only the aesthetic appeal of the LCD but also its functionality over time. It's essential for manufacturers and buyers to conduct a thorough cost-benefit analysis, ensuring that the selected cover glass aligns with both their budget constraints and performance expectations.