When it comes to selecting the right tempered glass for your specific needs, the choices can be overwhelming. With an array of options available, understanding the fundamental qualities and applications of tempered glass is crucial. As industry expert Dr. Emily Carson, a leading authority in architectural materials, states, "Choosing the right tempered glass is not just about aesthetics; it's about ensuring safety, durability, and functionality." Her insight highlights the importance of making an informed decision when assessing tempered glass products.

In this article, we will explore ten essential tips that will guide you in selecting the perfect tempered glass for your projects. From understanding thickness and safety ratings to considering thermal resistance and optical clarity, each aspect plays a vital role in the overall performance of the glass. With the correct knowledge, you can ensure that you are not only enhancing the visual appeal of your space but also investing in a product that meets safety standards and withstands the test of time. Whether you are a homeowner, designer, or contractor, these tips will provide you with a comprehensive understanding of how to choose the best tempered glass for your specific requirements.

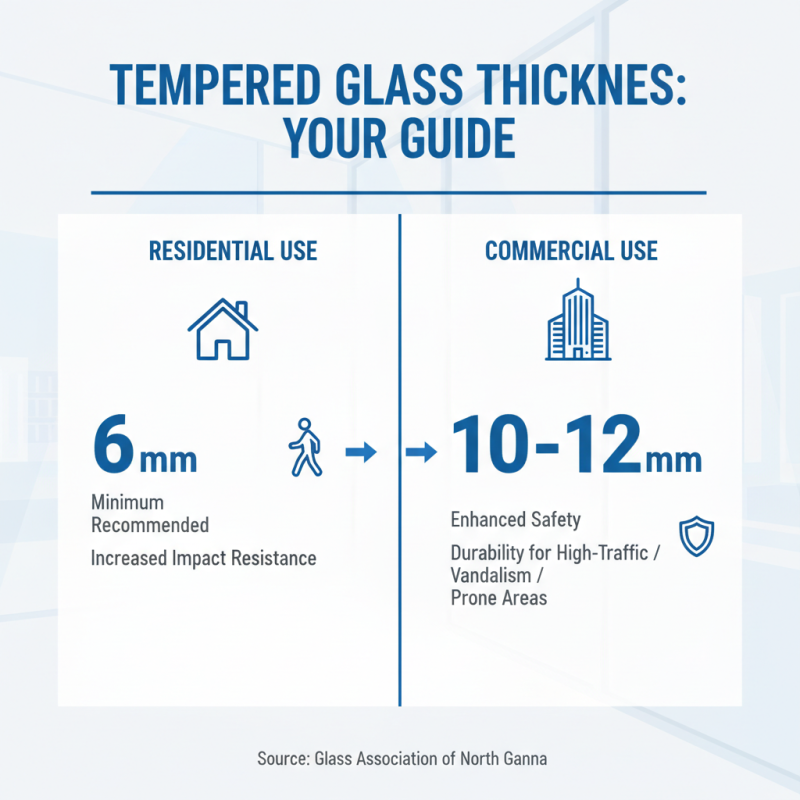

When selecting tempered glass for your project, understanding the key factors that influence its performance and suitability is essential. One fundamental aspect is the thickness of the glass. According to the Glass Association of North America, thicker tempered glass typically demonstrates greater resistance to impact, making it ideal for high-traffic areas or applications prone to vandalism. For residential use, a thickness of at least 6mm is often recommended, while commercial applications may require thicknesses ranging from 10mm to 12mm to ensure safety and durability.

Additionally, the thermal properties of tempered glass should not be overlooked. The International Glass Association highlights that tempered glass is designed to withstand significant temperature fluctuations, withstanding heat up to 250°F (121°C) without deformation. This resistance is crucial in settings such as kitchens or sunlit exteriors where heat exposure is common. Furthermore, considering the glazing options can impact energy efficiency. Low-emissivity (Low-E) coatings can reflect infrared energy while allowing visible light to enter, which enhances insulation and reduces energy costs in buildings. Therefore, evaluating these factors will help ensure the tempered glass meets the specific needs of your project effectively.

When selecting tempered glass, understanding the various types and their specific applications is crucial. Standard tempered glass, known for its strength and resistance to thermal stress, is commonly used in windows, shower doors, and glass doors. This type is processed by heating and rapid cooling, which makes it significantly more durable than regular glass. Its ability to shatter into small, blunt pieces instead of sharp shards enhances safety in residential and commercial environments.

Another type to consider is laminated tempered glass, which combines layers of glass and plastic for added strength and security. This variety is often utilized in applications where safety is paramount, such as in skylights, glass floors, and storefronts. The interlayer not only provides a barrier against shattering but also offers UV protection and sound insulation. Additionally, there is low-iron tempered glass, which has a higher clarity and is ideal for applications where aesthetics matter, such as display cases and balustrades. Understanding these distinctions will help you select the right type of tempered glass tailored to your specific needs.

This bar chart illustrates the importance rating for various factors to consider when selecting tempered glass for your needs. Each factor is rated on a scale of 1 to 10, with 10 being the most crucial. This guide can help you make informed choices based on your specific requirements.

When selecting tempered glass for various applications, key safety features should be a primary consideration. Tempered glass is manufactured through a process of extreme heating and rapid cooling, making it significantly stronger than regular glass. According to a report by the Glass Association, tempered glass can withstand thermal stresses and impacts that regular glass cannot, making it an ideal choice for environments where safety is paramount. This resilience is particularly important in applications such as shower doors, facades, and glass railings, where breakage could lead to serious injuries.

One vital safety feature to look for in tempered glass is its ability to break into small, blunt pieces rather than sharp shards, which reduces the risk of cuts and injuries. The National Institute for Safety and Health highlights that this property is crucial in high-traffic areas. Additionally, ensure that the glass meets relevant local and international safety standards, such as those set forth by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO).

These certifications indicate that the glass has undergone rigorous testing and adheres to safety regulations, providing peace of mind for both consumers and industry professionals. Evaluating these aspects will ensure that the tempered glass you choose not only meets aesthetic needs but also prioritizes safety.

When selecting tempered glass for a specific application, one of the most critical factors to consider is its thickness, as it has a direct impact on both strength and performance. Generally, tempered glass is available in various thicknesses, typically ranging from 4mm to 19mm, depending on the intended use. According to the Glass Association of North America, thicker glass not only enhances structural integrity but also increases resistance to thermal stress, which is essential for applications exposed to extreme temperature fluctuations.

For instance, a 10mm tempered glass can withstand significantly more impact and bending stresses compared to its 6mm counterpart, making it suitable for architectural applications where safety and durability are paramount.

Furthermore, the performance of tempered glass under thermal loads can be influenced by its thickness. Research from the American Architectural Manufacturers Association indicates that for applications such as shower enclosures or glass facades, the recommended thickness should be no less than 8mm, as this provides a robust barrier against thermal breakage.

Tempered glass subjected to sudden temperature changes is prone to risks if it's too thin, potentially leading to spontaneous shattering. Thus, choosing the right thickness is not just a matter of aesthetics but a crucial decision impacting both longevity and safety in various settings.

When selecting tempered glass, understanding the balance between cost and quality is crucial for making a wise investment. According to a report by the Glass Association, high-quality tempered glass, while potentially more expensive, significantly enhances safety and durability—qualities that can ultimately lead to cost savings in the long run. For instance, the service life of premium tempered glass can exceed 20 years, whereas lower-quality options may need replacement in as little as 5 to 10 years due to issues like thermal stress or breakage. This disparity not only affects budget allocation but also influences maintenance costs and overall project longevity.

Furthermore, industry data shows that the initial investment in quality tempered glass can yield impressive returns on investment, with some studies indicating that projects utilizing higher-grade materials experience around a 15% reduction in long-term maintenance costs. Additionally, the lifespan and performance of tempered glass in harsh weather conditions—such as extreme temperature fluctuations—are paramount considerations. Choosing quality over the lowest price point can ensure that the glass not only meets safety standards but also withstands external pressures over time, reinforcing the notion that in many cases, a higher price reflects greater value.